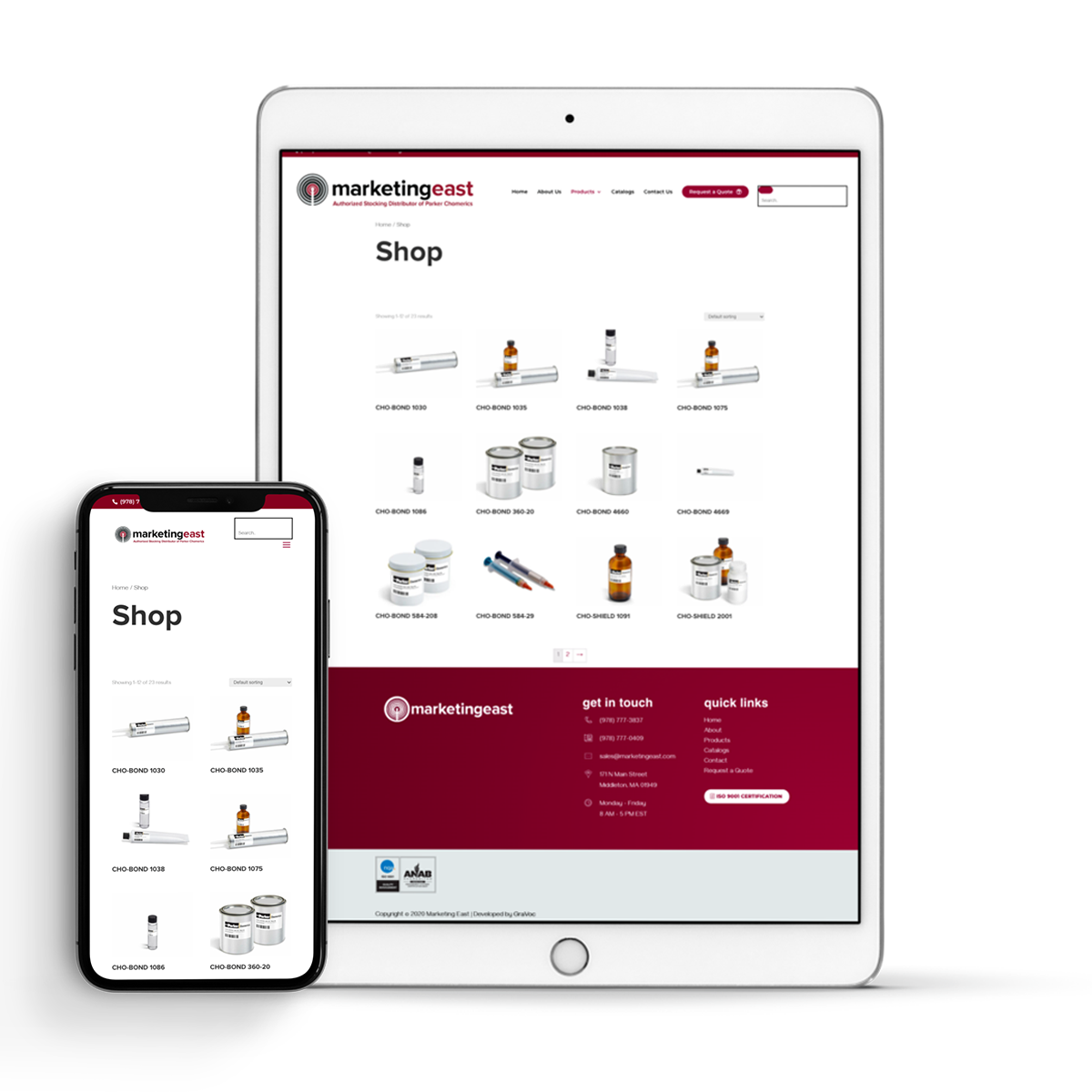

featured products

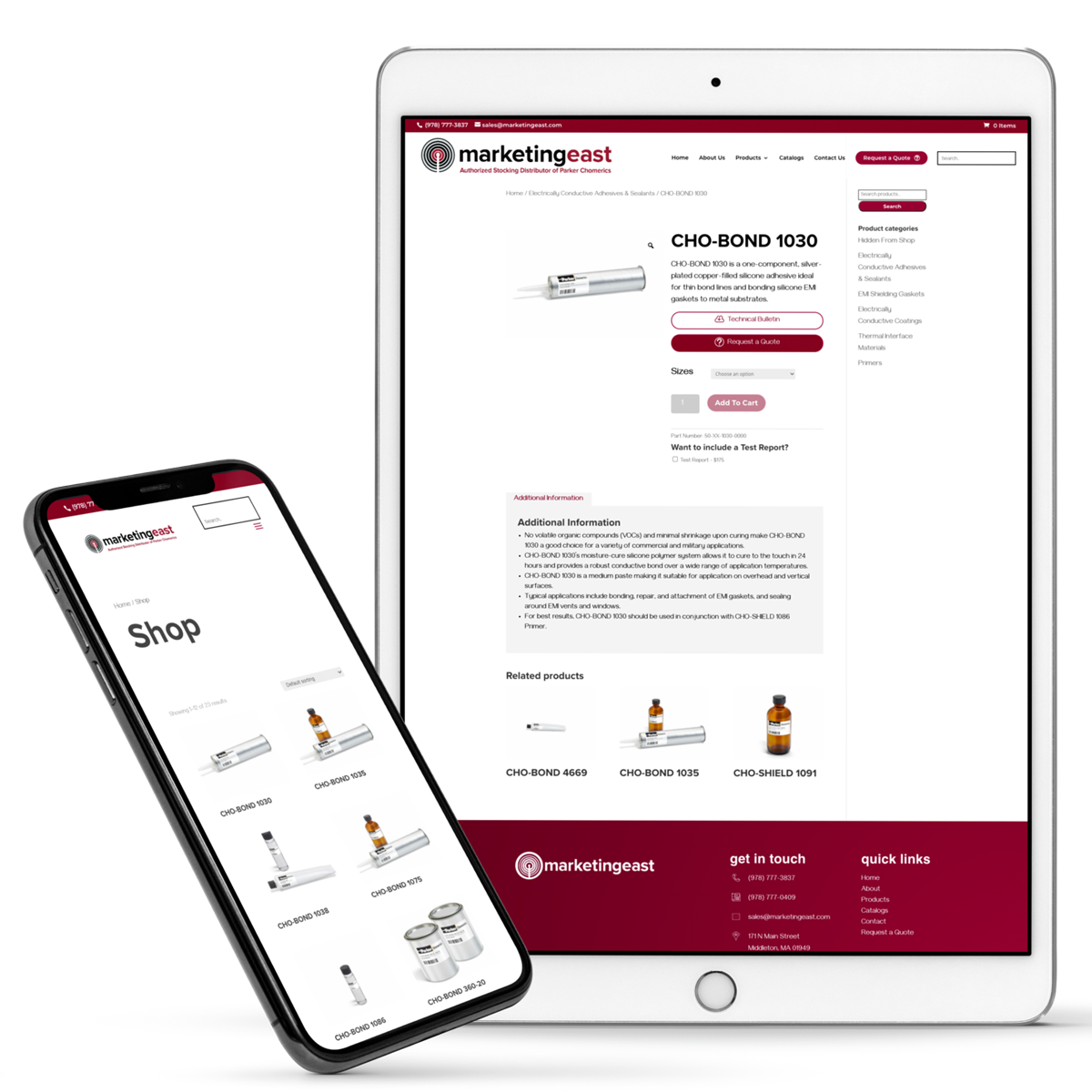

Electrically Conductive Adhesives & Sealants

These CHO-BOND products provide a strong bond & electrical pathway between 2 surfaces. These products are also gap fillers providing EMI shielding for electrical enclosures.

Electrically Conductive Coatings

The CHO-SHIELD products provide EMI shielding and grounding for electrical components and housings. They can be applied to both plastics and metals.

Thermally Conductive Materials

These thermally conductive products, including CHO-THERM, THERMFLOW and THERM-A-GAP GELS, are designed to create thermal management solutions for the most challenging applications.

why marketingeast?

Stocking Distributor

We stock Chomerics conductive sealants, adhesives & thermal interface materials.

Customer Service

Success is driven by our customers’ satisfaction.

Women-Owned

Marketing East has been woman-owned since 1985.

Quality Management

We are ISO 9001 certified.

Same Day Shipments

Marketing East can ship same day for all in-stock products.

Daily Pick-ups

Daily pick-ups at Chomerics allow us to ship products to you in the shortest amount of time.

Prompt Response

A representative will always answer the phone during business hours and we promptly respond to all emails and RFQs.

Stocking Distributor

We stock Chomerics conductive sealants, adhesives & thermal interface materials.

Customer Service

Success is driven by our customers’ satisfaction.

Women-Owned

Marketing East has been woman-owned since 1985.

Quality Management

We are ISO 9001:2015 certified.

Same Day Shipments

Marketing East can ship the same day for all in-stock products.

Daily Pick-ups

Daily pick-ups at Chomerics allows us to provide product in the shortest amount of time.

Prompt Response

A representative will always answer the phone during business hours and we promptly respond to all emails and RFQs.

start the conversion

Get in touch with our experts. We are here to help you.

get in touch

(978) 777-0409

171 N Main Street

Middleton, MA 01949

Monday - Friday

8 AM - 5 PM EST